Tungsten Disulfide Powder- And The Phase Of Preparation

Tungsten Disulfide Powder | cdn11.bigcommerce.com

Tungsten Disulfide powder is also termed WS2. Though the coefficient of relevance holds a lot of importance it is the properties that stays it apart from the rest. The methods along with the conditions have an important role when it comes down to the evolution of Tungsten disulfide powder. It is due to the reason that the preparation phase is segregated into three layers.

The moment term of tungsten disulfide emerges it is subject to high pressure or high-temperature conditions. Coming to the loading temperature in the coated material it tends to be in the bracket of 300,000 PSI. One of the pointers that you can consider is not to purchase MOS2 and go on to choose tungsten disulfide. Since the powder is expected to have one of the best coefficients of fiction their application areas tend to be at a limited level. One of the pointers that you need to consider is that it needs to be linked up with every application layer.

The moment you are going to purchase WS2 there may emerge a fixed pattern of coating. Close to a year do not expect any form of coating to emerge. A glass tile or resin that is tac filled that is due to its abrasive nature is expected to reduce the coating life. It is due to the nature of mould-saving components, that are expected to be compatible with all the components. In the moulding services, there is a requirement for some of a corrosion substance and it is due to the various storage facilities that it is expected to provide.

The capabilities along with features of Tungsten Disulfide Powder

Some of the capabilities along with benefits of tungsten disulfide powder are as follows

• The moment you tend to use WS2 lower fines are bound to emerge as you need to overcome the issues related to the lubrication

• One of the pointers to consider is that it is only the service life that has been extended, though the impact on the overall performance is excellent

• The lubricant is being maintained properly due to its structure.

• When the question of WS2 application curing occurs, baking is a critical feature. It works in such a manner that you are expected to hold temperatures to the bracket of 100,000 PSI. This is something that is operational at a specific temperature range.

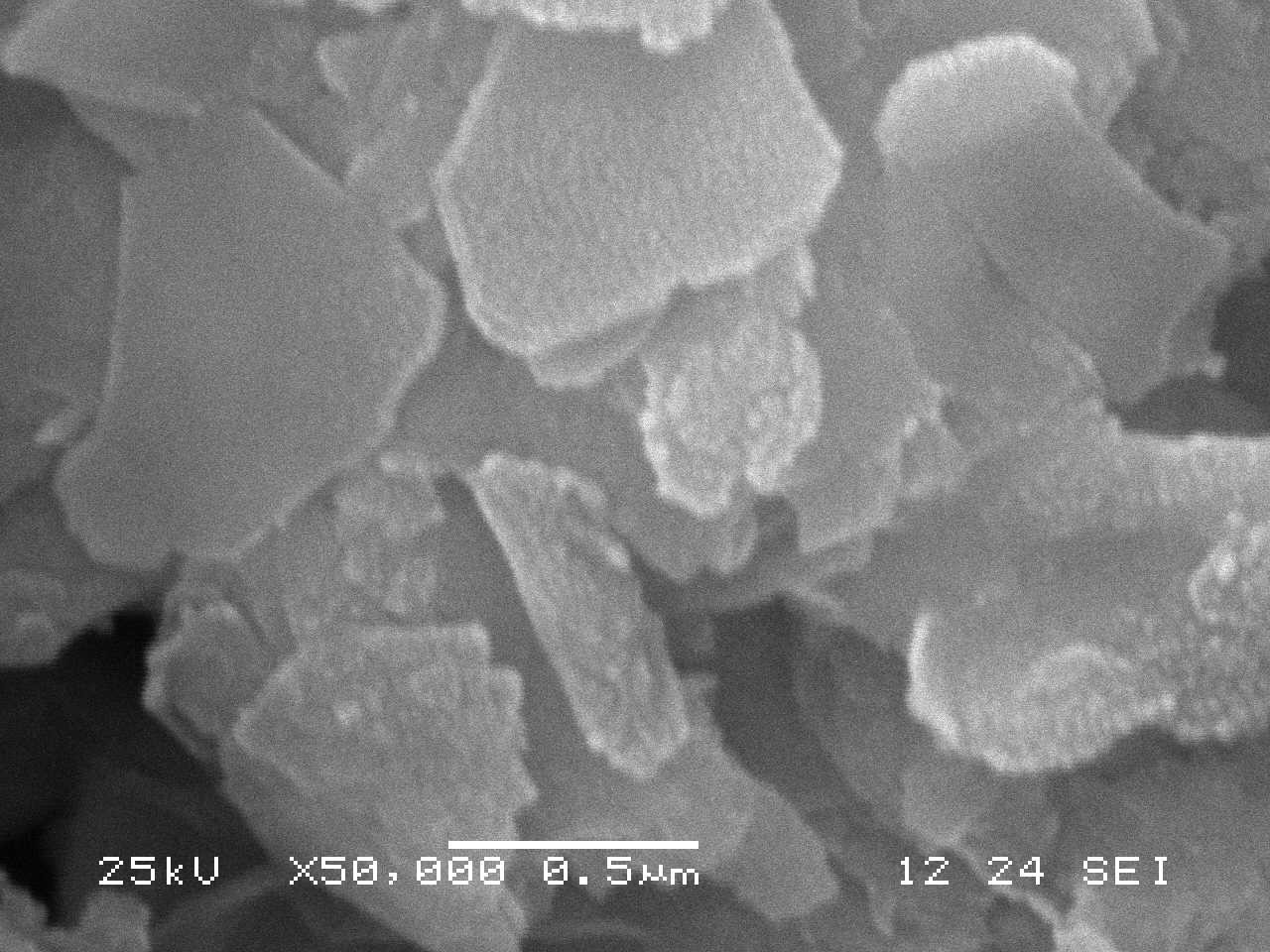

The purchase of tungsten disulfide powder has to be exercised with a lot of caution. Make it a point that you purchase a pure version and not an adultered form of the same. Even the particle size has to be given serious thought since it happens to be in the range of 0.06.